Search This Supplers Products:industrial videoscope manufacturerjoystick borescopesRVI inspection instrumentNDT equipmentwifi borescopeIR videoscope

Videoscope Technology: A Game Changer for Detailed Industrial Inspections

time2024/11/23

- Industrial videoscopes have revolutionized inspection processes across various industries by providing detailed, non-destructive evaluations of hard-to-reach areas. These advanced tools enhance efficiency, safety, and quality control in sectors such as aerospace, automotive, and power generation.

Industrial videoscopes have revolutionized inspection processes across various industries by providing detailed, non-destructive evaluations of hard-to-reach areas. These advanced tools enhance efficiency, safety, and quality control in sectors such as aerospace, automotive, and power generation.

Enhanced Efficiency and Reduced Downtime

Traditional inspection methods often necessitate partial or full disassembly of equipment, leading to significant downtime. Industrial videoscopes eliminate this need by allowing quick, non-invasive inspections, thereby reducing machinery downtime and boosting overall productivity.

Improved Safety Standards

In hazardous environments—such as high-temperature zones, radioactive sites, or areas with toxic chemicals—industrial videoscopes enable inspections without exposing personnel to danger. This capability is crucial for maintaining safety while performing essential checks.

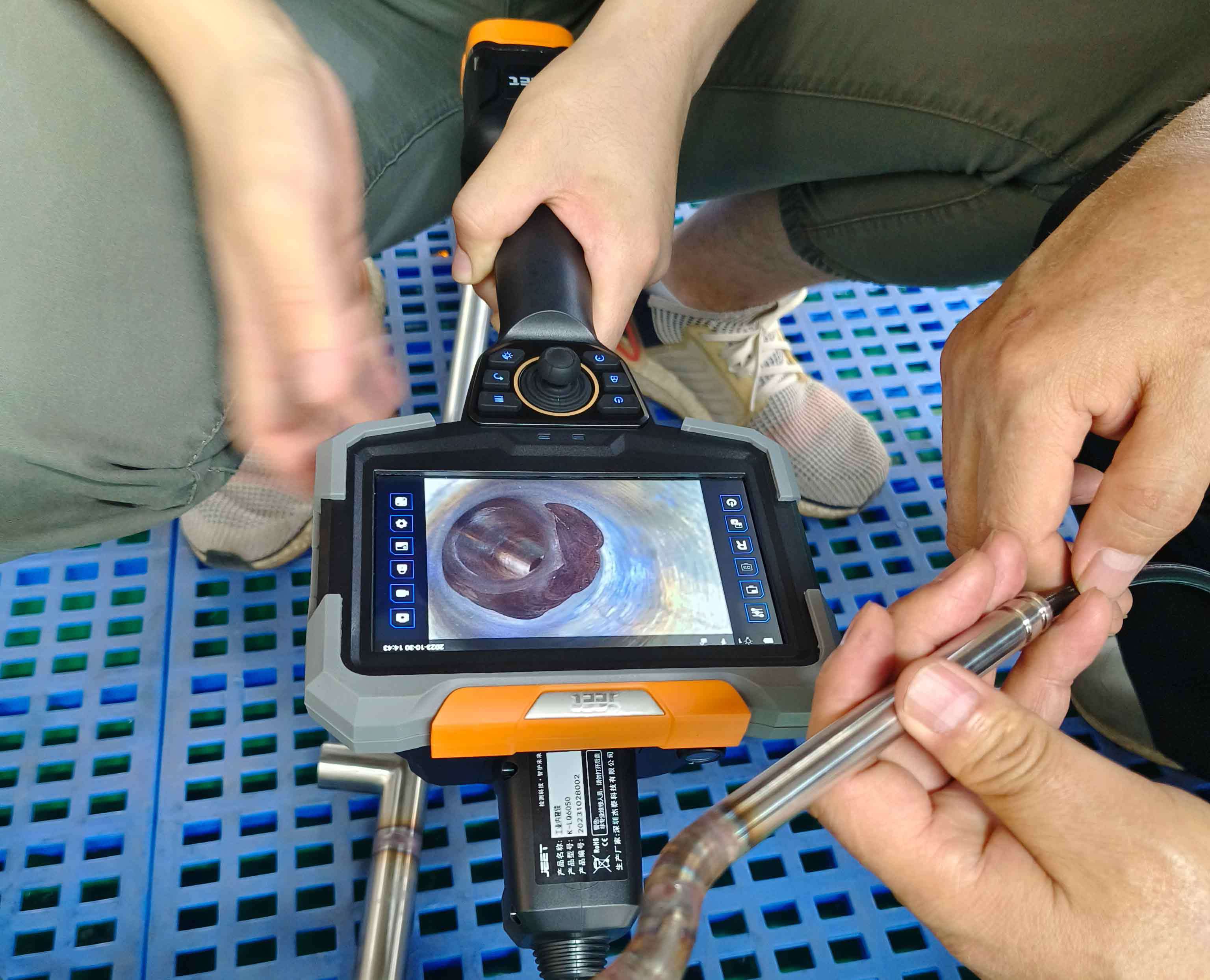

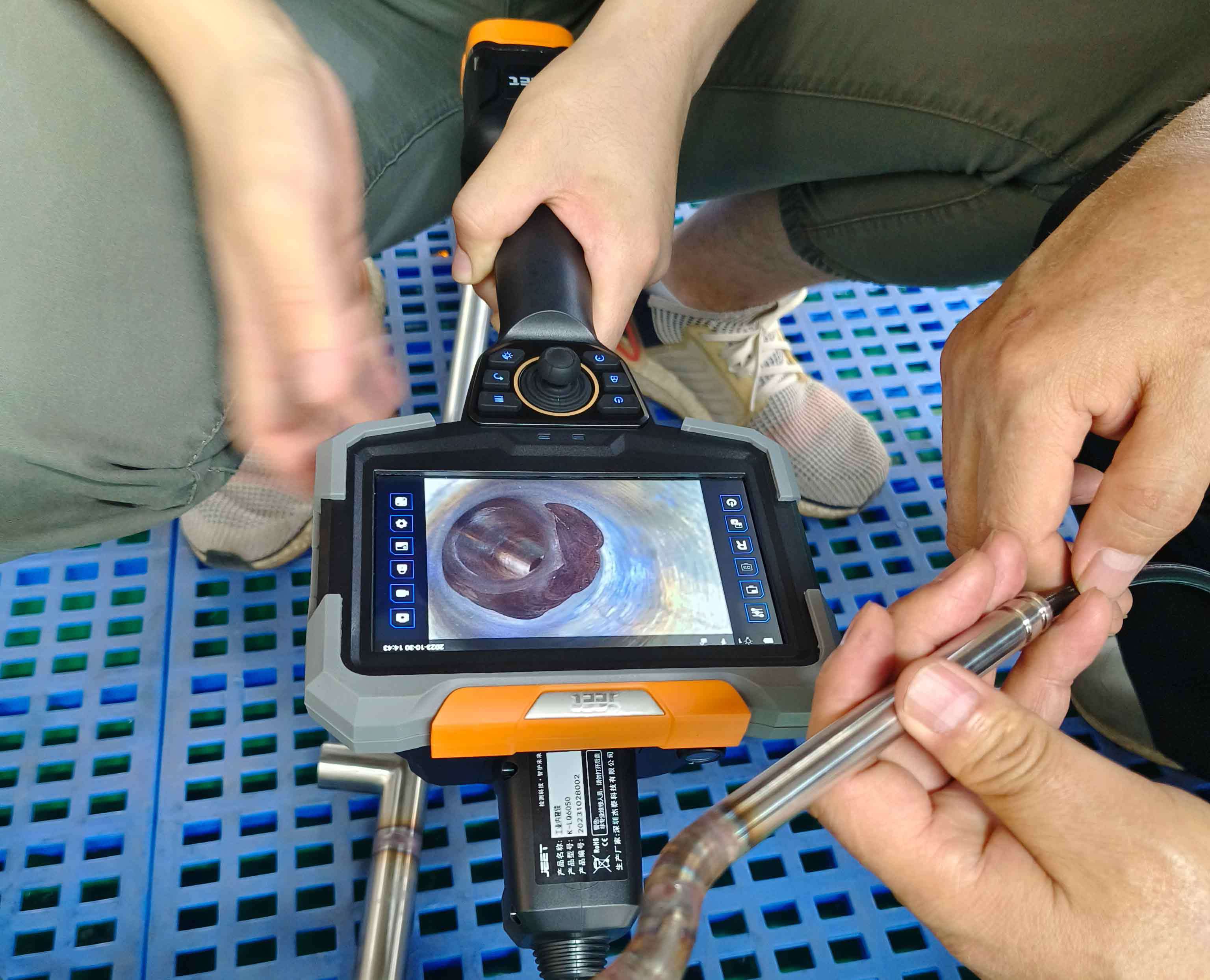

High-Resolution Imaging for Quality Control

Equipped with high-definition cameras, industrial videoscopes capture detailed images and videos, facilitating precise assessments of components and assemblies. This detailed visual documentation is invaluable for quality control, ensuring products meet stringent standards before reaching the market.

Early Defect Detection

The high-resolution imaging capabilities of videoscopes allow for the early detection of defects, cracks, or blockages, enabling timely interventions that prevent minor issues from escalating into major problems.t

Portability and Ease of Use

Modern videoscopes are designed to be portable and user-friendly, making them accessible for various inspection tasks. Their lightweight and compact designs allow for easy transportation and operation in diverse industrial settings.

In summary, industrial videoscope technology has become a game-changer for detailed inspections, offering enhanced efficiency, improved safety, and superior quality control across multiple industries.